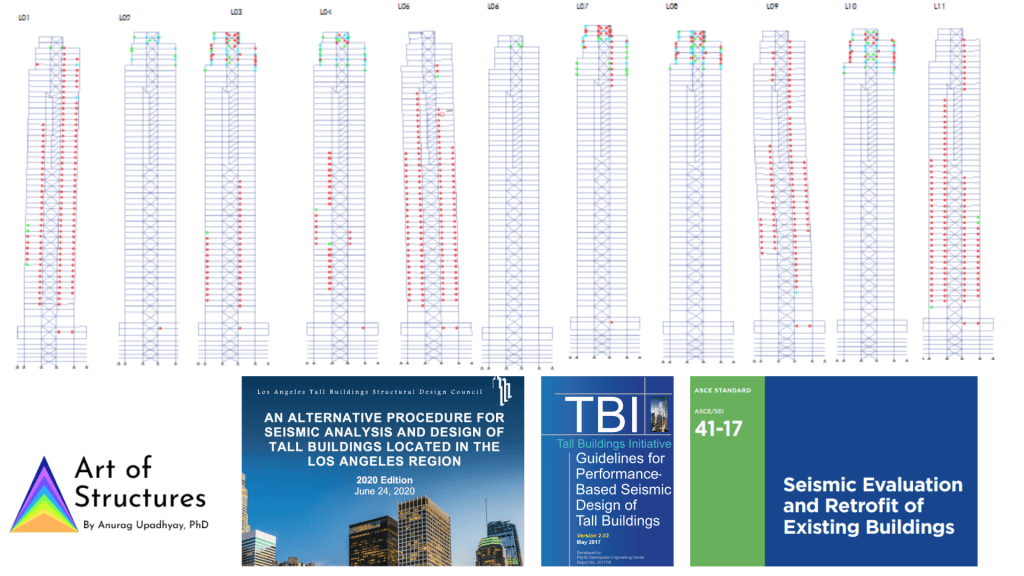

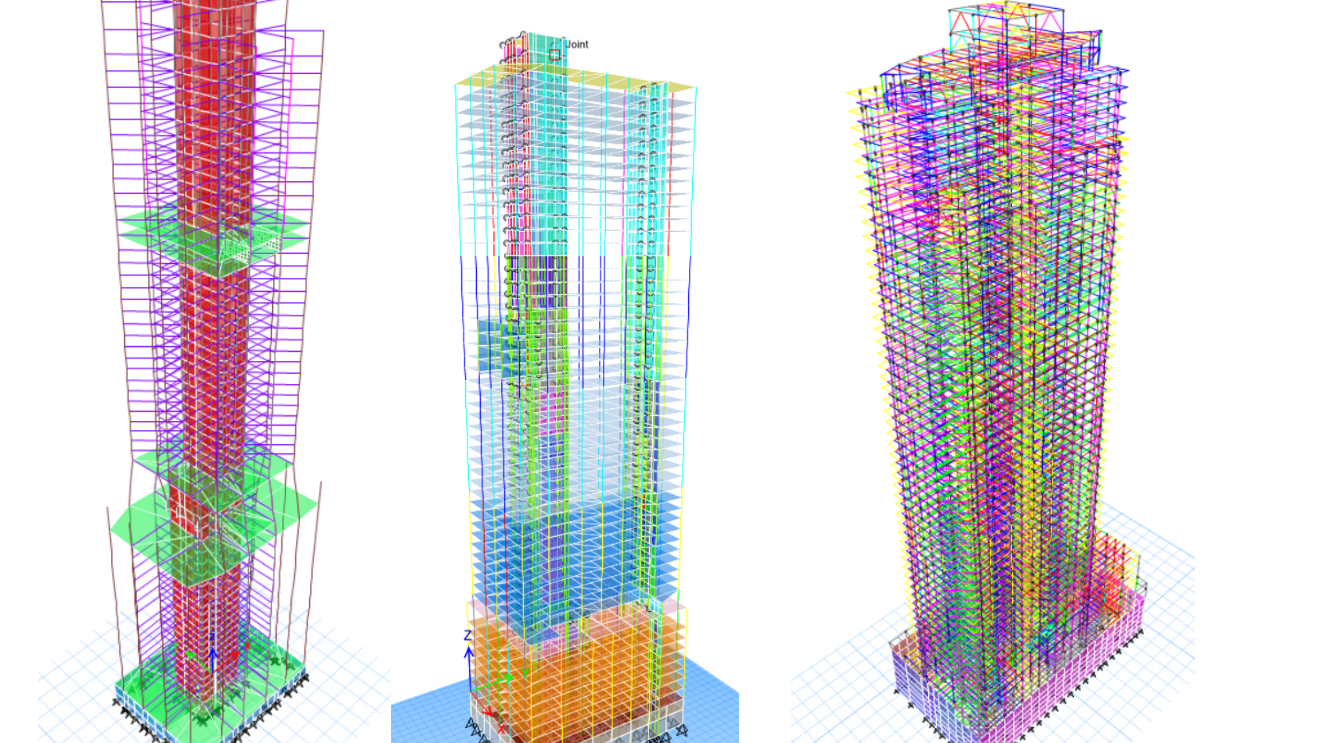

I developed 65 nonlinear analysis models in 2024 for various projects at Tipping. These projects were a mix of new design and seismic retrofit. After seeing my LinkedIn post, many engineers reached out to me wondering how I could do it despite nonlinear analysis being a time-consuming process.

Nonlinear structural analysis is the basis of a performance-based design (new or retrofit) procedure. It is a time-consuming process with a lot of possibilities for errors. In today’s post, I’ll talk about a few major reasons that make this process time-consuming.

1. Setting up the Nonlinear Model

This step takes the longest time and the most engineering effort. Ideally, this step is broken into multiple sub-steps such as gathering historical information, calculating component properties, importing properties into the software, etc. But, to talk about the challenges, I’ll combine all the challenging parts of this step into one.

To begin with, the engineer has to justify what structural components will be modeled with nonlinear behavior. Some “primary” structural components are designed to dissipate the input seismic energy through nonlinear action. For example, flexure in moment frame beams, coupling beams, column hinges, and shear wall hinges. These will definitely be modeled with a nonlinear material model. However, these components are (generally) not expected to exhibit significant nonlinearity in shear behavior.

However, the engineer on record (EOR) can decide to utilize the nonlinear shear behavior in these components to benefit the design. The EOR has to justify this behavior using calculations, engineering judgment, and a rigorous peer review.

Calculating beam hinge properties is quite straightforward. You just have to follow ASCE 41 backbone inputs based on the sectional design. The beam hinge behavior (almost) stays consistent during an earthquake. The nonlinear behavior of the structural components with varying axial loads is difficult to quantify.

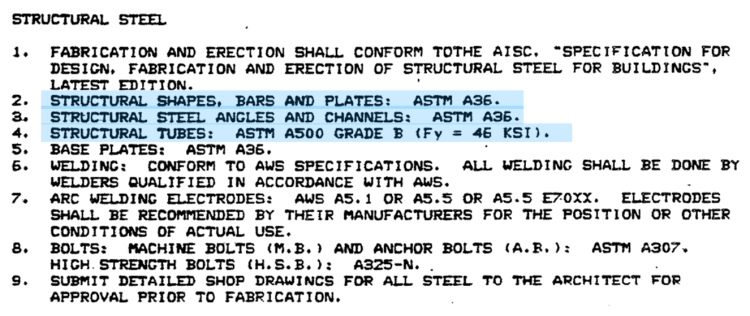

For a seismic retrofit project of an existing building, gathering information on the material properties (concrete, rebar, structural steel, weld) is also an important step. ASCE 41 provides default lower-bound material strength for historical materials.

Historical structural drawings sometimes have shocking structural detailing. Sure, it must have made sense 70 years ago. Some of the structural detailing will definitely not qualify the current code provisions. You have to be really careful while making assumptions about the structural capacities.

2. Ground Motion Selection and Scaling

A licensed Geotech engineer is tasked to select a set of representative ground motions scaled to the design response spectrum. The structural engineers can, sometimes, perform this step for concept phase studies. I have seen cases where we ran the analysis with the selected ground motions only to find large drift results for one or two ground motions, flagging them as statistical outliers. We then had to request a revised set of ground motions. But, the exercise could easily consume up to one week of the work schedule.

3. Analysis Convergence Issues

You have finished developing the nonlinear analysis model which works fine for modal and gravity (dead load) analysis. But, convergence issues start to appear as soon as you start running the nonlinear time-history analysis. Now you have to find out what is causing the non-convergence by looking at the mode shapes for possible anomalies, understanding the deformed shape produced by the incomplete analysis, reading the log file for warning messages, or worst: replacing the nonlinear components with linear elastic behavior one by one to find out what component type is causing the non-convergence.

Refresher: The analysis software runs multiple internal iterations at each analysis step to find a solution where the internal forces are balanced with the external ones. This is referred to as “convergence”. If the program is unable to find a solution, it accepts the error within a tolerance limit provided by the engineer. If it accepts a large error at each step,

“Convergence issues start to appear as soon as you start running the nonlinear time-history analysis.”

4. Design Iterations/ Re-design

Engineering design is iterative. You know the drill for the elastic design, assume the structural system, pick parameters, calculate design forces, perform component design, iterate until converge to final sizes. A Performance-based design process also deals with re-design but not as many as the elastic design. You analyzed the nonlinear building model using a suite of 11 ground motions and found that some components have exceeded their acceptable rotation/strain limit. Now you have to redesign these components and re-run all those analysis again. Do it until all the structural components in your building satisfy the acceptance criteria.

How many time do you have to do it? It all depends on your workflow. You can carefully choose a workflow that could reduce the iterations. At Tipping, we have run nonlinear time-history analyses for projects still in their concept phase. We did it because we could. Our workflow allows us to quickly create nonlinear models and post-process the results. I have also seen projects that are too large to do this in any phase. I have had nonlinear models of 50+ story buildings that took 5 days to finish a suite of 22 ground motions, and required 3 design iterations to get to a satisfactory design.

Planning to include soil-structure interaction in your nonlinear model? Be very mindful.

5. Peer review

All your work (design, nonlinear models, assumptions, code compliance, etc.) is reviewed by one or more independent reviewers appointed by the authority having jurisdiction. Once a week or bi-weekly, you send your work to the reviewers and receive a response the week after. Do we need a peer review? Absolutely! A nonlinear design method has so many uncertainties associated, that a peer review process is important to eliminate any biased engineering judgment. Peer reviewers are helpful and provide valuable comments. I have seen peer review comments actually saving time and effort, thus saving money.

Although a PBD approach is more expensive and time-consuming, it results in better structural design in most cases. Understanding nonlinear analysis helps innovate structural design.

Share this article with your friends and colleagues. Start your learning groups where you can grow together. I will talk more about nonlinear analysis in my next article.

Cheers,

Anurag Upadhyay, Ph.D.

Discover more from Art of Structures

Subscribe to get the latest posts sent to your email.

Leave a comment