The real reasons behind the collapse of an under-construction high-rise building in Bangkok, Thailand, during the Myanmar earthquake can only be understood after a detailed investigation. In this article, I’ll focus on some of the possible reasons based on the social media video evidence.

This article is purely for educational purposes and doesn’t necessarily represent my employer’s views.

Bangkok’s skyline has been growing for many years to accommodate the population growth as a result of the booming economy. About 9 million people lived in the city as of 2021, and nearly 17.4 million lived within the surrounding metropolitan region. The oldest high-rise building of Bangkok, 495 feet tall, 43-story Baiyoke Tower I, was constructed in 1994. The current tallest building in the city is the 1033-foot-tall Magnolia Waterfront Residences, which has 70 floors. The design and construction of skyscrapers are not something new to the city’s industry.

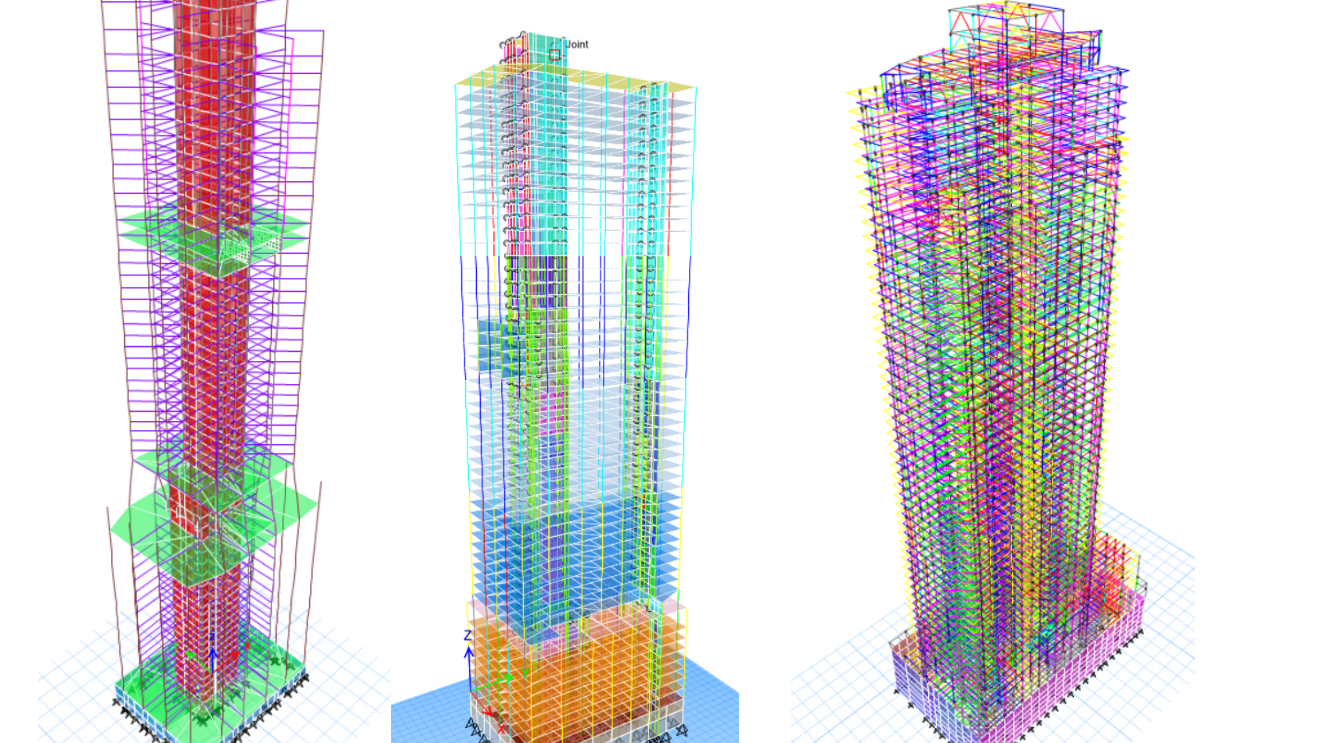

On 28 March 2025 when a 7.7 magnitude earthquake hit Mandalay in Myanmar. Bangkok, which is about 1000 km away from the earthquake epicenter, was shaken by earthquake waves. Many structures collapsed, and most (almost all) of them were older buildings that were (probably) not designed with the latest seismic codes. One of the collapsed buildings was a 33-story (449 feet tall) new, under-construction building. The building’s structure was topped out, so arguably, the seismic-force-resisting system (SFRS) was already in place. Based on the available data, this building’s SFRS consisted of a concrete core-wall system.

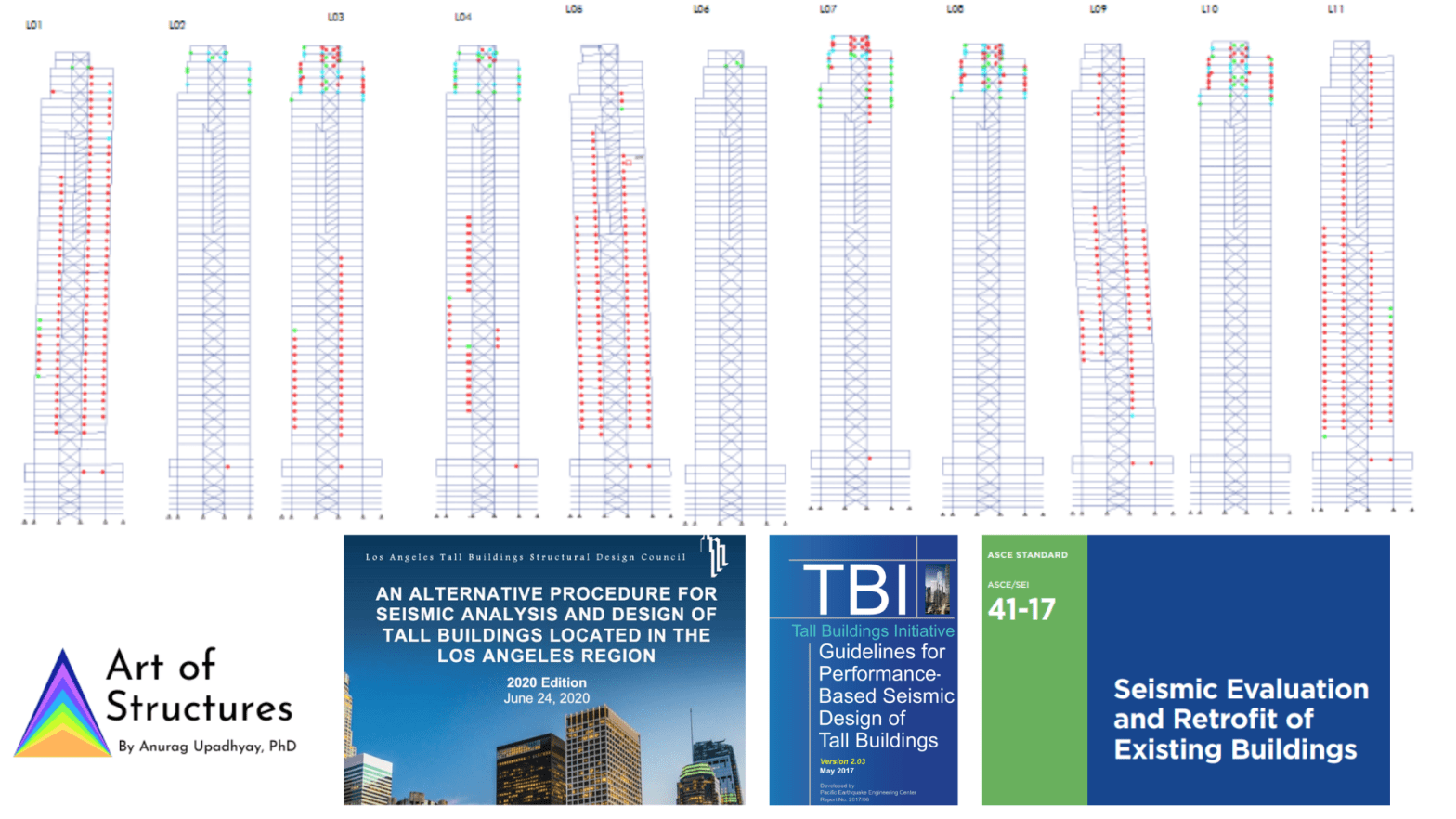

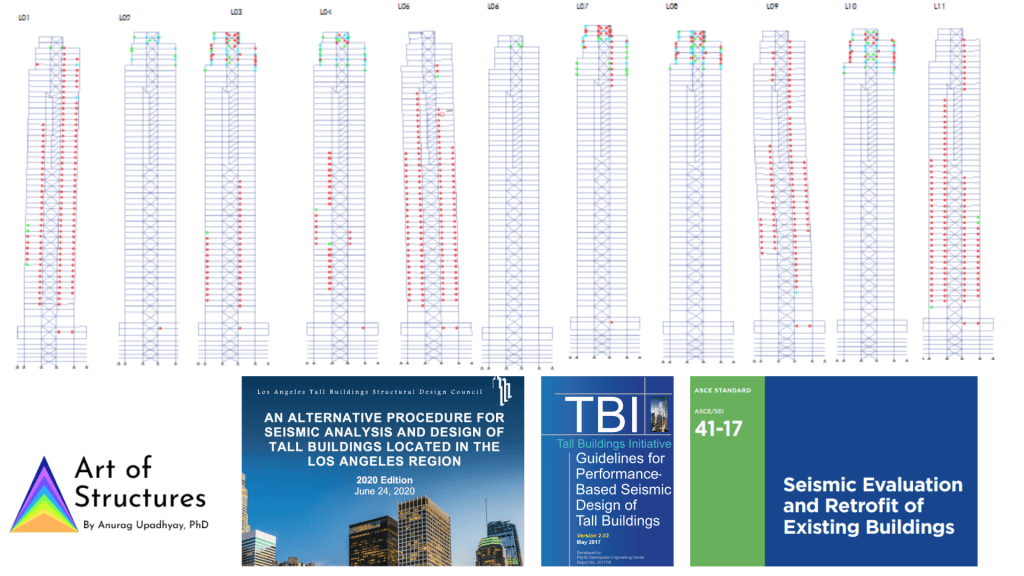

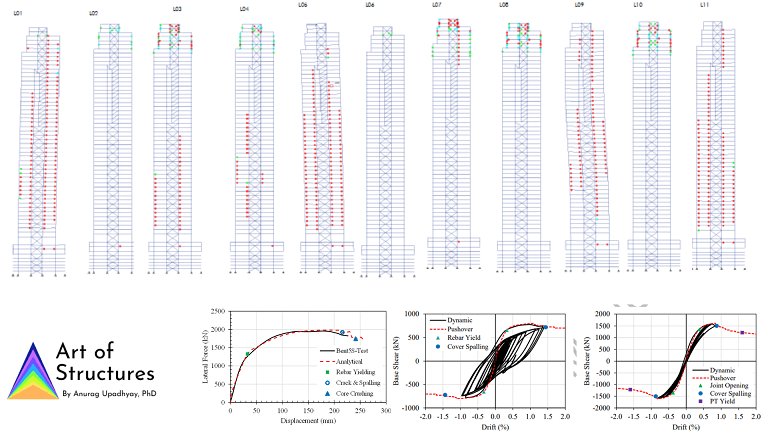

The video below shows how tall buildings behave under far-field and near-field ground motions differently. Far-field ground motions have long-period waves that excite the primary modes (first few modes) of a building. Under such conditions, the tall buildings experience large lateral drifts, leading to the development of plastic hinges in shear walls at the bottom stories.

I compiled a video (below) with 3 different views of the collapsing tower with my best effort to align the movement. Here are the three angles,

1. The left view, although difficult to see, shows the concrete shear wall core moving vertically down.

2. The center view shows a wide-angle view of the building’s front with concrete columns. Note that the first columns to fail were at the level 2nd from the top. NOT the top slender columns.

3. The right view shows the zoomed-in view of the top floors. You can observe that the center of the building starts to move vertically downward. This is an indication that the failure started either in the middle columns or the shear wall core.

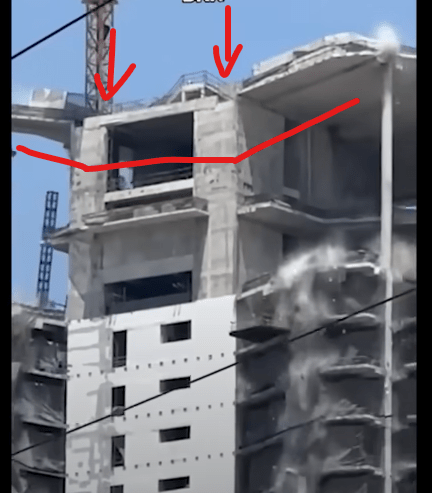

Here is a screenshot of another video that showed the top floors from the shear wall side of the building. The image shows the shear wall core moving downward, pulling the post-tensioned slabs with it, while the concrete columns hold them up. This caused the slab to bend, straining the slab-column and slab-wall connections. This could have caused punching shear failure in the slabs at the column support. The concrete dust at the column-slab connection is an indicator of such failure. You don’t see such dust at the slab-wall connection.

Now, based on my observation above, here is my hypothesis of the sequence of events that happened within 2 seconds,

Event 1. The concrete shear wall core lost its gravity load-carrying capacity at the base. This caused the vertical downward movement in the entire core. The next few paragraphs focus on what could have happened at the base.

Event 2. The core tried to pull the prestressed concrete slabs with it, causing punching shear failure at the columns closest to the core.

Event 3. The moving slabs started to pull the columns on the other side of the building, increasing the column shear demand. The short columns on the 2nd level from the top failed in shear, starting a complete story collapse.

Event 4. Breaking of prestressing tendons could have caused a shockwave, leading to stress amplification in other columns and amplifying the progressive collapse.

Event 5. While the upper floors started to collapse, the tall columns at the bottom story failed in shear.

A question that baffled me is, “If the shear wall core at the base failed first, why didn’t it cause a failure in the bottom columns first instead of the columns at the top, as seen in the video?” I am not sure. It could be that the prestressed slab got disconnected from the shear wall due to excessive rotation.

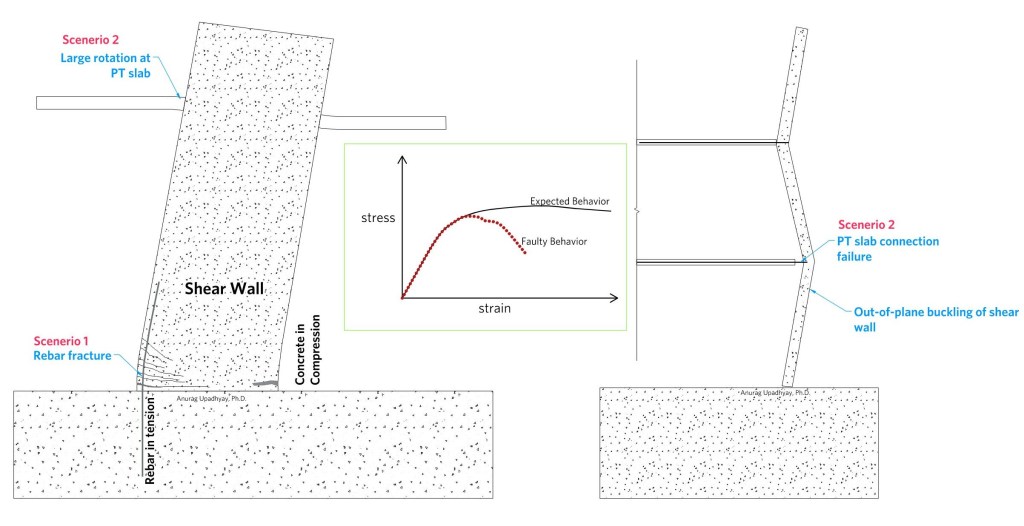

Here are two scenarios that could have played out to cause the shear wall core to collapse.

Scenario 1

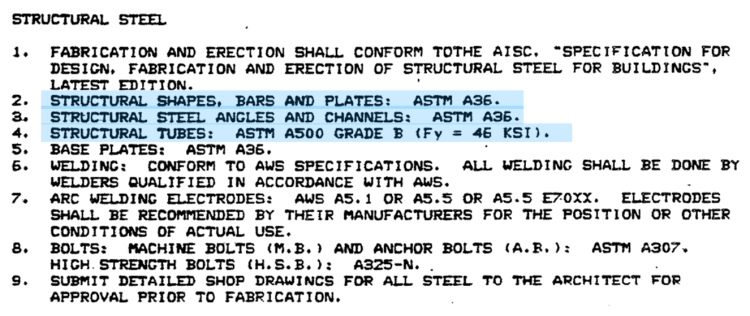

When subjected to lateral forces, the concrete shear walls are designed to develop a plastic hinge over the lower stories, generally at the base. A plastic hinge is a combination of rebar yielding and concrete damage, which dissipates the input seismic energy via controlled damage under cyclic loading. Mild-steel rebar has a great ability to stretch beyond its yield point before it fractures. This quality is a result of the thermo-mechanical process used to manufacture the rebar. Countries around the world have standards set in place to achieve a desired amount of “stretch” in the rebar to be sold for construction.

But, what if the rebar used in the construction is faulty and fails prematurely (see the stress-strain curve in the image below)? When pushed laterally by the seismic forces, the shear wall experiences overturning motion. As a result, the group of rebar at the extreme end of the wall undergoes stretching and yielding, thus developing a plastic hinge at the wall base.

With a faulty rebar fracturing without achieving a large strain after the yield point, the concrete at the other end of the wall would crush immediately. This, in some cases, could even lead to the loss of the gravity load-carrying capacity of the shear wall.

Scenario 2

Another hypothesis is that the PT slab to the shear wall connection failed due to excessive rotation. Once the slab is detached, the clear height of the shear wall increases almost twofold, making it vulnerable to buckling. The buckled shear wall core could collapse with such a high axial load. The collapsing core would pull the prestressed slabs down, leading to slab failure (punching?) at column supports. With such a failure on multiple floors, a collapse mechanism brings the entire building down vertically instead of overturning. Such a mechanism is used for controlled demolition of buildings (see video below).

Of course, these are just the hypotheses for now. Hopefully, the research community will find the answers soon. What do you all think about the collapse? Coming up with possible theories is a great way to learn. You should have them too, and start discussion groups.

We will talk about more structural analysis in the next newsletter.

Cheers,

Anurag Upadhyay, Ph.D.

Leave a comment